Round Pipe & tube Polishing Machine

Price 450000.00 INR/ Unit

MOQ : 1 Unit

Round Pipe & tube Polishing Machine Specification

- Polish Type

- Abrasive polishing / Buffing

- Usage & Applications

- Surface polishing, deburring, and finishing of round pipes and tubes

- Grade Standard

- Industrial Grade

- Application Surface

- Round Pipes & Tubes

- Accessories

- Polishing belts, brushes, dust collector

- Form

- Machine

- Finish Type

- Mirror / Satin / Matte (as per requirement)

- Application Areas

- Furniture, Railings, Automotive, Engineering Industries

- Power Source

- Electric

- Power

- 4 15 kW (depending on model)

- Type

- Round Pipe & Tube Polishing Machine

- Material

- Stainless Steel / Mild Steel

- Capacity

- Variable depending on model (typically 10 to 100 mm diameter pipes)

- Computerized

- No

- Automatic Grade

- Semi-Automatic / Automatic

- Thickness

- For pipes and tubes ranging from 1 mm to 8 mm

- Air Pressure

- 0.6 0.8 Mpa (where applicable)

- Voltage

- 415 V / 3 Phase / 50 Hz

- Size

- Approx. 2600 mm x 900 mm x 1400 mm

- Weight

- Approx. 1200 kg

- Color

- Machine Gray / Blue

- Maintenance

- Low & easy to maintain

- Dust Extraction

- Integrated or external dust collector (optional)

- Lubrication

- Centralized or manual lubrication

- Suitable Material Polished

- Stainless Steel, Mild Steel, Aluminum, Brass, Copper Pipes

- Feeding Speed

- Adjustable, up to 10 meters/min

- Noise Level

- <85 dB

- Surface Roughness Achievable

- Down to Ra <0.2 m (mirror finish models)

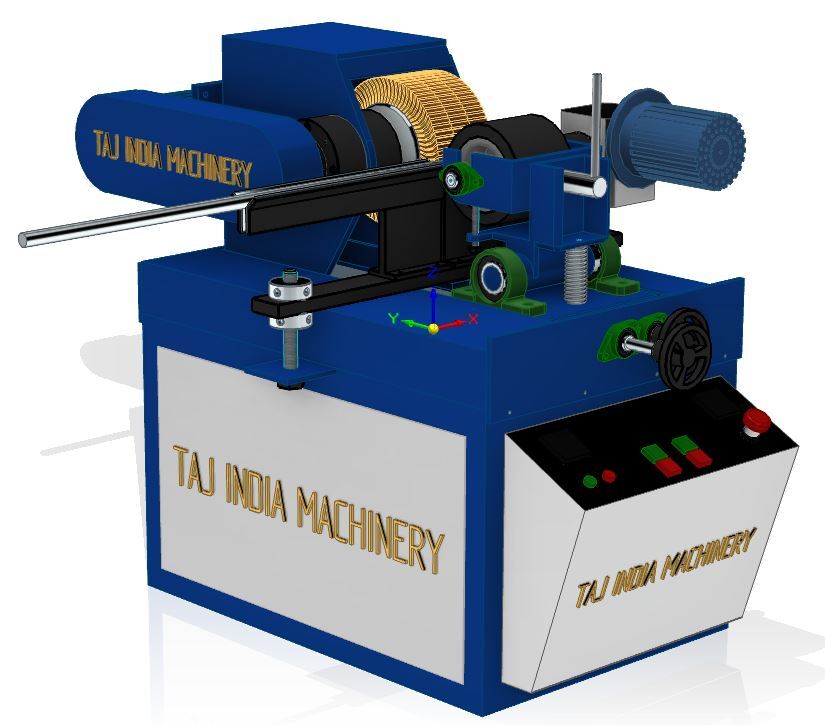

- Motor Type

- Induction Motor

- Pipe Diameter Range

- 10 mm 100 mm

- Coolant System

- Optional

- Polishing Belt Size

- Standard 100 x 2000 mm or model-specific

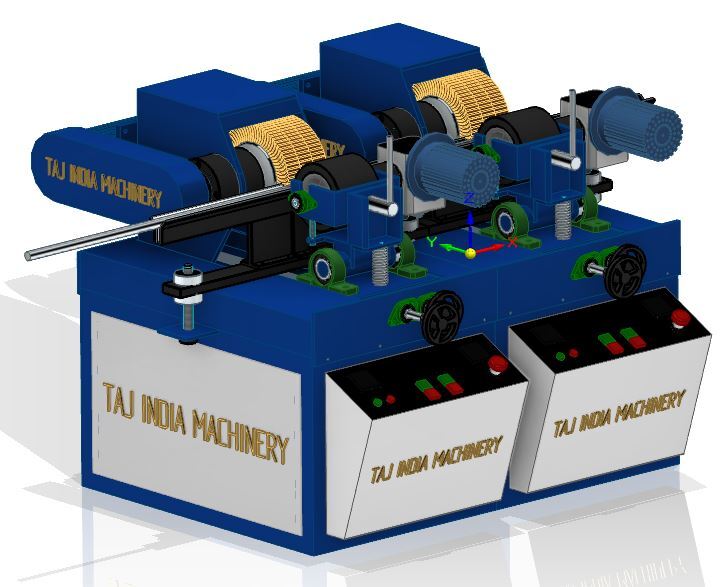

- Machine Structure

- Heavy-duty rigid frame construction

- Operator Requirement

- Single or dual operator

- Control Panel

- User-friendly with safety interlocks

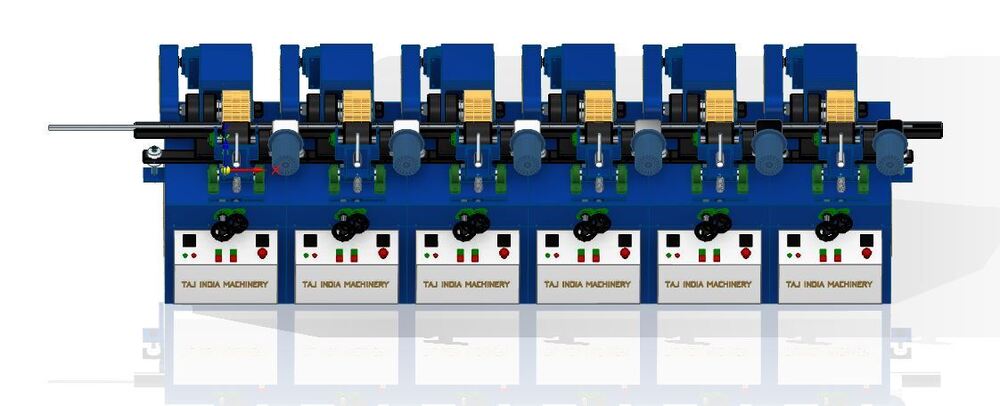

- No. of Polishing Heads

- 1 to 6 (model-specific)

Round Pipe & tube Polishing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- NEW DELHI

- Payment Terms

- Cash in Advance (CID)

- Delivery Time

- 2 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Round Pipe & tube Polishing Machine

Introducing the Round Pipe & Tube Polishing Machine-the inestimable best-seller for surface finishing. This must-have equipment boasts up to 6 imposing polishing heads and a heavy-duty, rigid frame, ensuring magnificent results with every use. Sizzling adjustable feeding speeds reach up to 10 meters/min, catering to pipe diameters from 10 mm to 100 mm. The user-friendly control panel, induction motor, and maintenance-friendly design exemplify ergonomic excellence. Engineered for stainless steel, mild steel, aluminum, brass, and copper pipes, this machine delivers mirror finishes down to Ra <0.2 m-making it indispensable for industrial-grade polishing applications.

Versatile Applications & Competitive Edge

The Round Pipe & Tube Polishing Machine excels in both standard and specialized applications, including surface polishing, deburring, and finishing tasks. Suited for furniture, railings, automotive, and engineering industries, its flexible usage type enables semi-automatic or automatic operation. Competitive advantages include a robust frame, low maintenance requirements, and centralized lubrication, ensuring high productivity and minimal downtime across diverse production environments.

Export, Packaging & Quick Dispatch Details

With swift outlay for procurement and quick dispatch times, the Round Pipe & Tube Polishing Machine is shipped via major FOB ports in India. Each unit is packaged meticulously to minimize expenditure on replacements due to transit damage. The machine enjoys a strong presence in the major domestic markets, serving manufacturers, suppliers, and exporters across India with reliable, cost-effective solutions for pipe and tube finishing needs.

Versatile Applications & Competitive Edge

The Round Pipe & Tube Polishing Machine excels in both standard and specialized applications, including surface polishing, deburring, and finishing tasks. Suited for furniture, railings, automotive, and engineering industries, its flexible usage type enables semi-automatic or automatic operation. Competitive advantages include a robust frame, low maintenance requirements, and centralized lubrication, ensuring high productivity and minimal downtime across diverse production environments.

Export, Packaging & Quick Dispatch Details

With swift outlay for procurement and quick dispatch times, the Round Pipe & Tube Polishing Machine is shipped via major FOB ports in India. Each unit is packaged meticulously to minimize expenditure on replacements due to transit damage. The machine enjoys a strong presence in the major domestic markets, serving manufacturers, suppliers, and exporters across India with reliable, cost-effective solutions for pipe and tube finishing needs.

FAQ's of Round Pipe & tube Polishing Machine:

Q: How does the feeding speed adjustment improve the polishing process for various pipe sizes?

A: The adjustable feeding speed, up to 10 meters per minute, allows optimal control over polishing for different pipe diameters and surface requirements, enhancing finish consistency and productivity.Q: What types of materials can be polished using this machine?

A: This machine accommodates stainless steel, mild steel, aluminum, brass, and copper pipes, delivering high-quality finishes from satin to mirror grades as per industrial standards.Q: When should the optional coolant system or dust extraction be considered for operation?

A: The optional coolant system is recommended when working on high-temperature applications or extended polishing cycles, while integrated or external dust extraction is suitable for environments requiring strict particulate control.Q: Where can the Round Pipe & Tube Polishing Machine be used effectively?

A: It is ideal for applications in furniture manufacturing, railings, automotive production, and various engineering industries that demand superior pipe surface finishes.Q: What are the main benefits of the heavy-duty rigid frame construction?

A: The robust frame ensures stability, reduces vibration, and increases the lifespan of the machine, resulting in consistent, high-quality polishing and lower maintenance costs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Round Pipe & tube Polishing Machine Category

Semi Automatic Cutlery Polishing Machine

Price 470000.00 INR / Unit

Minimum Order Quantity : 1 Piece

Automatic Grade : Other, Semi Automatic

Material : Stainless Steel & ABS Body

Color : Silver & Grey

Knife Polishing Machine

Price 540000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : SemiAutomatic

Material : MS

Color : GREEN

Warranty : 1 YEAR

Hinge Counter Polishing Machine

Price 75000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : SemiAutomatic

Material : MS

Color : Green

Warranty : Yes

Single Spindle Hinges Polishing Machine

Price 475000.00 INR / Unit

Minimum Order Quantity : 1 Piece

Automatic Grade : SemiAutomatic

Material : MS

Color : Green

Warranty : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free